Major Technology.

Technology Overview

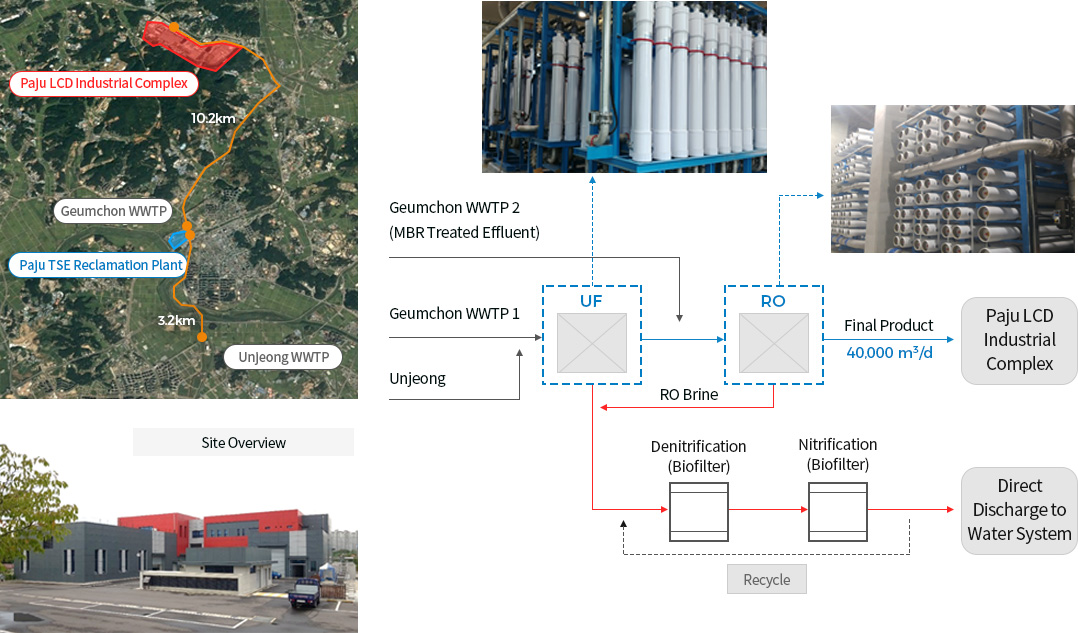

We have built expertise for optimization of both process and operation of treated sewage effluent(TSE) reclamation plant employing UF-RO processes and RO brine treatment based on experience of full cycle from business development, construction and long term operation of Paju TSE reclamation plant.

Strong Points

- Smart O&M that collects and analyzes all operation data for process monitoring and optimization since operation commencement in 2018.

- RO brine treatment technology that improves the water quality below the discharge water quality standards.

(the only TSE reclamation plant in Korea that directly discharges the treated RO brine to a river) - Operation optimization technology based on the experience to cope with fluctuations in quantity and quality of TSE from three different municipal wastewater treatment plants.

- Produces final product water using UF-RO technology that meets the influent water quality standards set by the customer (i.e. LCD industrial complex) (TOC 0.5 ppm and below).

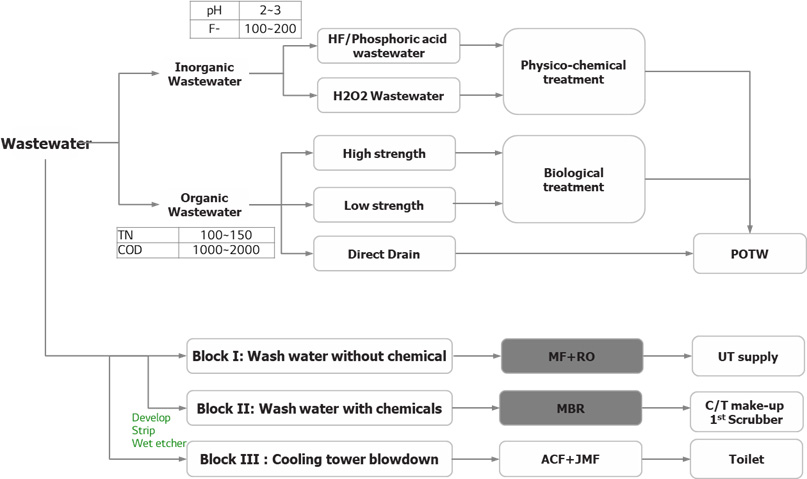

Ultra Pure Water Treatment and Wastewater Reuse Technology for the Display Industry

Technology Overview

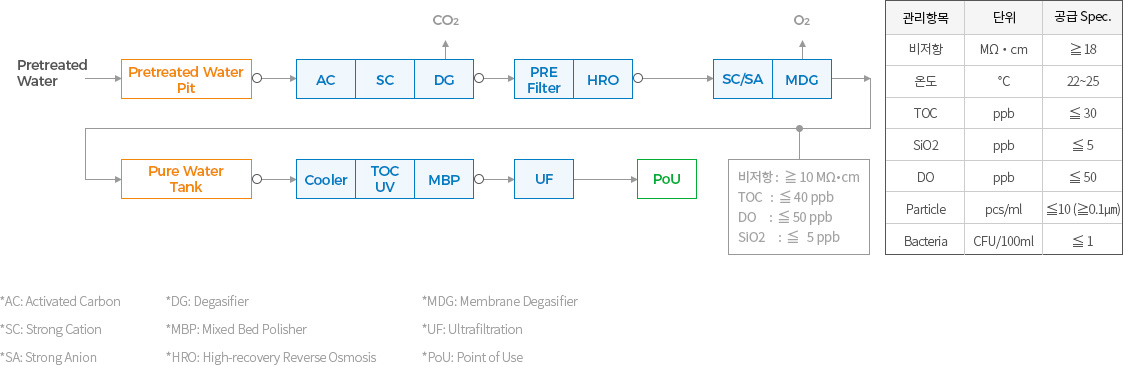

Technology that can perform the water treatment process, including planning, design, construction and operation management, of producing ultra pure water and reusing wastewater at display and semiconductor manufacturing process that use a large amount of high quality water.

Strong Points.

- Solution technology that satisfies various customer needs through close cooperation with manufacturing process from the planning stage.

- Able to establish reuse plan and perform design and construction by characteristics of wastewater by separating various types of wastewater generated during manufacturing process from source.

- Technology for optimal water supply, wastewater reuse and treatment based on knowledge in display manufacturing process.

Ultra Pure Water Production Process

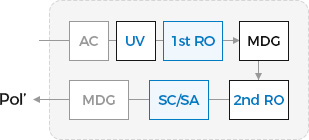

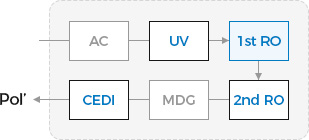

RO Process Comparison

| Section | High-Recovery RO + SC/SA | 2 Pass RO + SC/SA | 2 Pass RO + CEDI |

|---|---|---|---|

|

Process configureation

Make-up

Chemical use process

|

|

|

|

|

Use of Ion Exchange Resin : chemical requirement for resin regeneration

|

Use of Ion Exchange Resin : chemical requirement for resin regeneration

|

Electric deionization(CEDI) : electricity consumption

|

Separation / treatment / reuse of wastewater

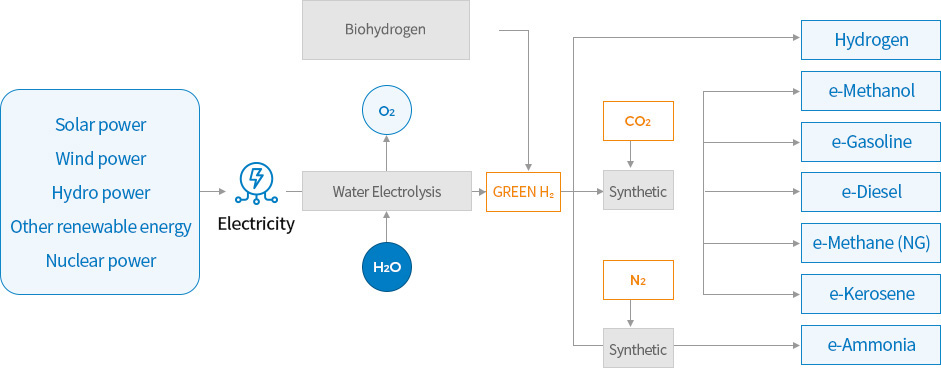

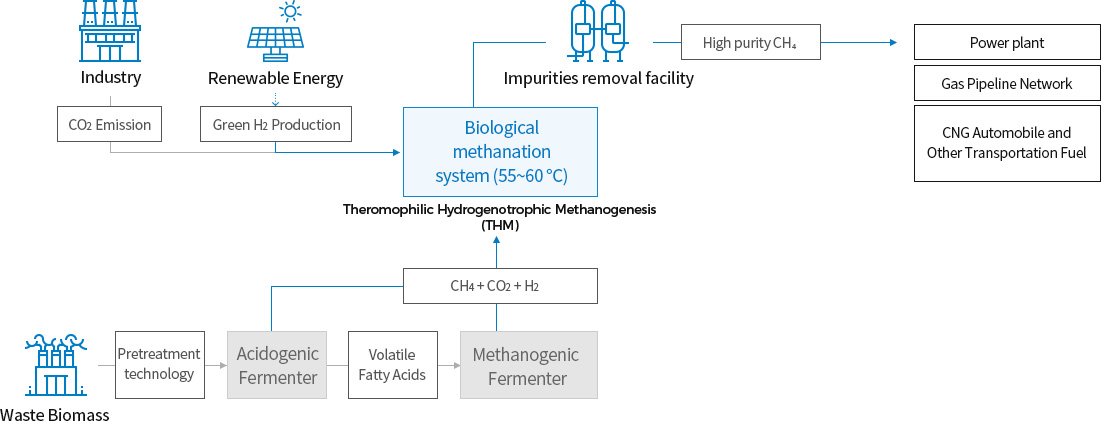

THM Technology to convert CO₂to methane

Technology Overview

- A technology that can convert carbon dioxide, one of the typical greenhouse gases, into carbon neutral fuels (aka e-fuel) compatible with existing devices utilizing fossil fuel. The technology employs microbiological reaction of carbon dioxide and green hydrogen made by electrolysis using renewable energy or from bio-waste.

- One of the P2G(Power to Gas) technologies which can mitigate the volatility of renewable energy by converting surplus power into methane gas.

-

The development was initiated from a joint research project with KEPRI(Research institute of Korea Electric Power Corporation).

- Research Title: Technology Development for CO2 Bio-Electrochemical Methanation, 2017~2019 -

Installation and operation of a test-bed at the Water Reuse Technology R&D Center located in the Jungnang Water Reclamation Center of Seoul Metro City, as a part of a national research project funded by MOTIE(Ministry of Trade Industry and Energy).

- Research Title: Development of biomethanation technology for bio-upgrading biogas using CO2 from flue gas of industrial plant, 2017~2021

Strong Points.

- Biologically converts CO2 and H2 into methane by microorganism at high temperature (Thermorphilic Hydrogenotrophic Methanogenesis, THM), using less energy compared with thermochemical conversion technology.

- Produces high purity methane by applying anaerobic digestion technology that converts organic waste, such as food waste, into methane.

- Immediately applicable to existing natural gas infrastructure and demand.

E-FUEL Concept Diagram

Installation Case

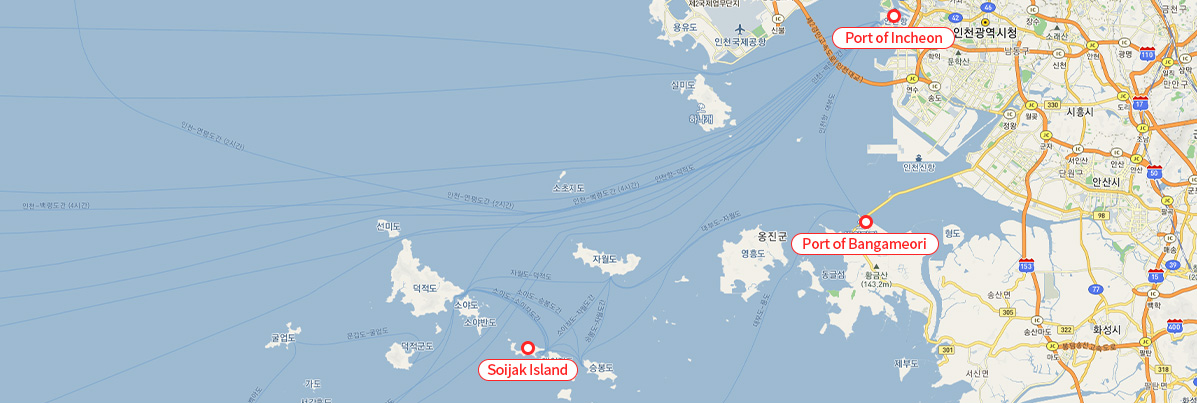

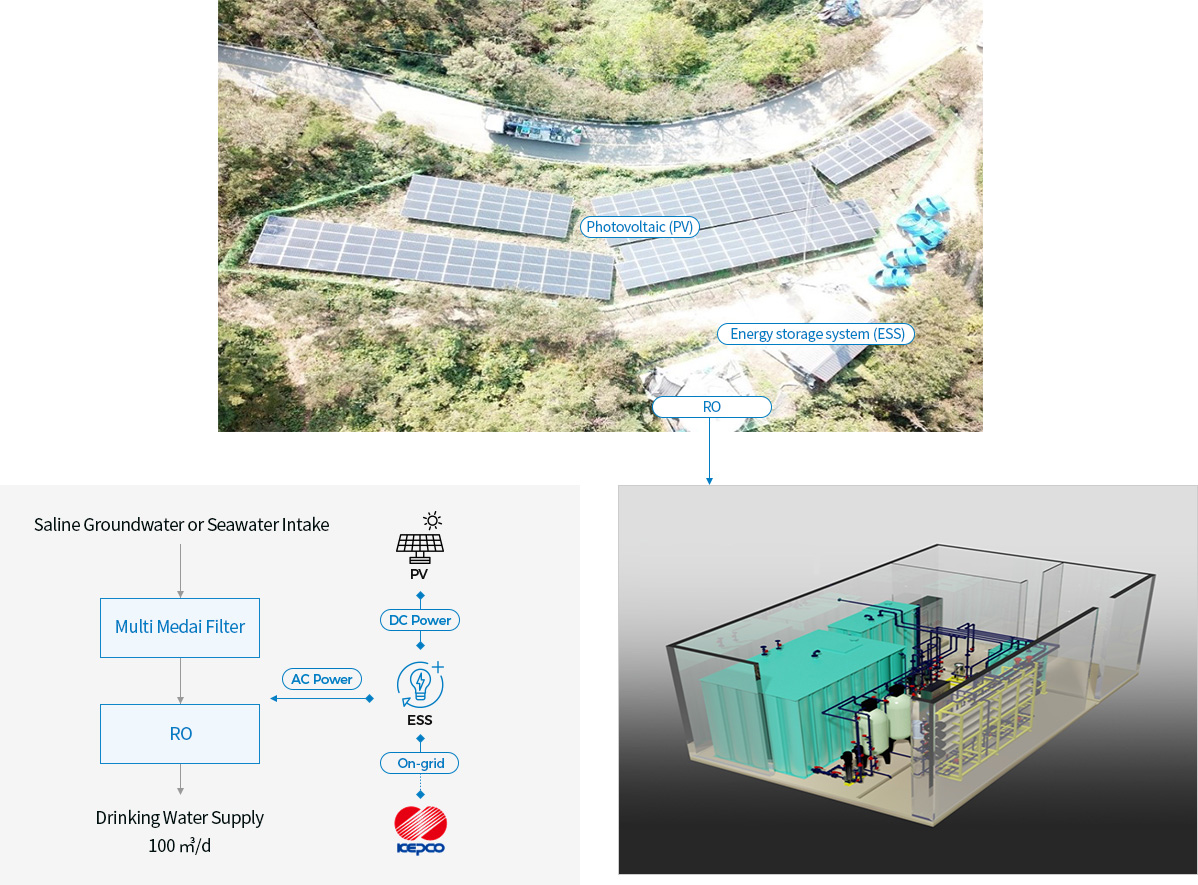

PROES™ : A trademark of Energy self-sufficient desalination technology consisting of PV, ESS and RO systems

Technology Overview

- Energy self-sufficient small-sized desalination technology consists of PV, ESS and RO desalination for islands or resort facilities with lack of fresh water nor power supply.

- MOTIE(Ministry of Trade Industry and Energy)-sponsored research project:

Building intelligent platform for renewable energy and water self-sufficient islands.

Strong Points.

- Designs the optimal capacity of PV, ESS and RO by considering various environmental conditions such as sunshine hours, water demand and source water quality.

- Applicable to brackish and sea water desalination depending on various source water conditions.

- Eco-friendly technology with membrane cleaning method using microbubbles instead of using chemicals - no wastewater generated other than RO concentration.

Installation Case : Incheon Soijak island

[Process Diagram]

[3D image of RO]